Find and eliminate dangerous underground threats.

Cross Bore Inspection services from Hydromax USA can help you quickly and accurately identify and remove hazards from your system. We leverage the most comprehensive suite of technologies available.

understand the present | protect the future

Dedicated cross-bore industry leader.

At Hydromax USA, we’ve been a dedicated industry leader for 20 years, solely focused on ensuring natural gas cross bore safety. Pioneers of the Cross Bore Safety Association, we set gold standards and offer comprehensive solutions for the entire cross bore inspection program. Our experienced team and cutting-edge technology ensure precision and efficiency from planning to execution. With an unblemished record, we’ve inspected a linear expanse equivalent to circumnavigating the globe twice, assuring clients of unparalleled results and peace of mind. As leaders in cross bore inspection services, we provide tangible value, offering safety inspections, gas leak surveys, locating and GIS mapping, and custom software development to natural gas partners nationwide.

Advanced cross bore programs built on experience.

Our innovative cross bore programs boast distinctive capabilities, featuring GPS field data collection equipment with real-time corrected accuracy down to 3%. Our field personnel undergo extensive training on best practices and troubleshooting, ensuring maximum accuracy in recording positions. The use of higher-accuracy equipment enhances confidence in data review, lowers system risk, and improves overall results. Leveraging high-resolution aerial imagery, data analysts can confirm risk areas with a smaller tolerance and a higher degree of confidence. Digital Cross Bore reports delivered via MaxLink are not only searchable but also linked to related GIS data for future reference and studies, stored in digital layers accessible through the utilities’ system. Hydromax USA provides support for ESRI, GE Smallworld, and various other GIS platforms.

Our program approach.

Hydromax USA’s Cross Bore Inspection program is designed with a focus on gathering high-quality data, strategically eliminating the potential for human error in the field collection and validation process crucial for identifying and mitigating cross bores. Central to our program are five overarching methodologies: Project Ramp-Up, Inspection Methodology, Scoping Process Development, Mapping and Data Review Precision, and the Proximity Team. Each element contributes to the program’s comprehensive approach, ensuring accuracy, efficiency, and the highest standards in data collection and validation throughout the cross bore inspection process.

Project ramp-up

Agreement and permit negotiation management to gain access to municipalities and sewer operators resulting in:

- Significant savings for utilities

- Mutually beneficial partnerships with the sewer operators help them identify problems before they worsen and often help them meet their inspection goals

- Turnkey services, managing all business licenses, insurance, and bonds required by every municipality and sewer operator

Key Benefit: Enhanced relationships with municipalities, inspectors, and sewer operators.

Inspection methodology

- Inspect all mainlines and laterals within the assigned job site.

- Utilize best-in-class CCTV cameras and robotics to traverse every inch of pipeline.

- Exhaustive suite of troubleshooting methods with cleaning, hydro excavation, and more.

- Videos and GPS points are reviewed by a highly trained Data Analyst.

- Conflicts? Proximity Technician in the field reviews all measurements to ensure accuracy and confidence in clearing inconclusive inspections.

Key Benefit: A thorough process ensures no risk areas are left uninspected.

Scoping process development

Develop rules specific to your environment/region to support:

- Mainline inspections

- Push camera inspections

- Proximity review

- Data analyst review

Identifiable risk area review with existing datasets:

- Gas service cards

- As-builts

- City sewer and right-of-way records

- GIS

- Other paper or digital records available to us

Key Benefit: Ensures inspections are performed only on at-risk facilities.

Mapping & data review precision

- High-resolution imagery to aid data analysts, beyond the scoped gas risk.

- Custom workstations for maximum resolution to ensure no cross bores or installation damage is missed.

- Specially developed software ensures no risk areas are left uninspected.

- High-accuracy GPS data creates a complete system map for both gas and sewer facilities and our data

- Analysts review 100% of the collected data to ensure that all potential conflict areas are free of risk and that no sewer branches are missed due to roots, water sags, or poor visibility due to dirty camera lenses.

Key Benefit: No inspections are cleared in the field; Hydromax USA offers the only Cross Bore Inspection program in the industry that holds inspections to this rigorous standard.

Our proximity team

Our Proximity team is comprised of highly-trained individuals with extensive GIS, construction, and survey backgrounds – allowing us to eliminate risk in the most challenging conditions by confirming the location of sewer and gas facilities when they are otherwise inaccessible.

Key Benefit: Inaccessible locations are cleared by highly trained team members to ensure seamless project completion.

Dedicated to innovation and safety.

Our advanced digitalization technologies help gas utilities capture critical data today to help solve the biggest challenges of tomorrow.

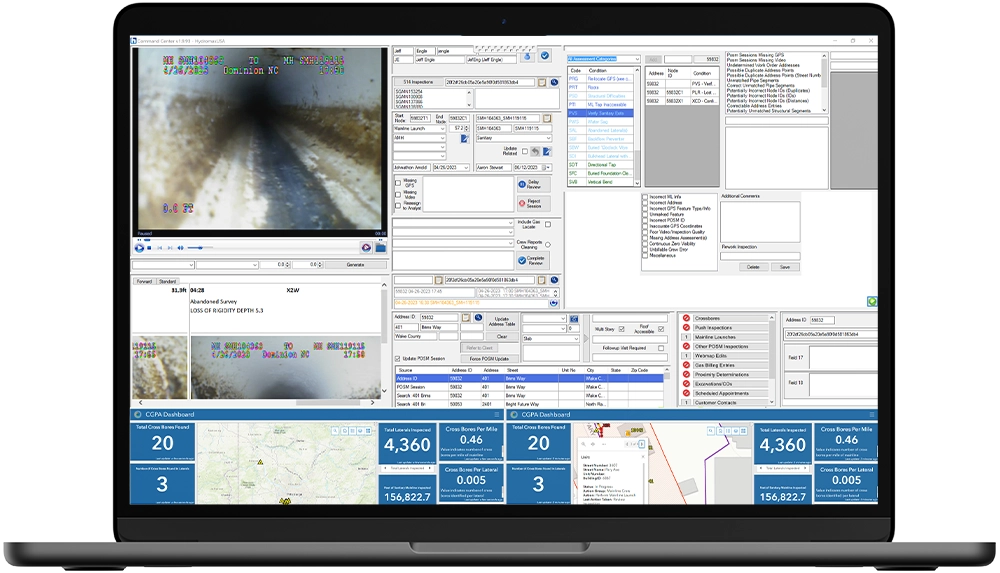

TAKE COMPLETE CONTROL OF YOUR CROSS BORE PROGRAM

Collect, integrate, and display millions of critical data points within a single, easy-to-understand interface. Manage every aspect of your program with uncompromised quality control and unlimited business intelligence.

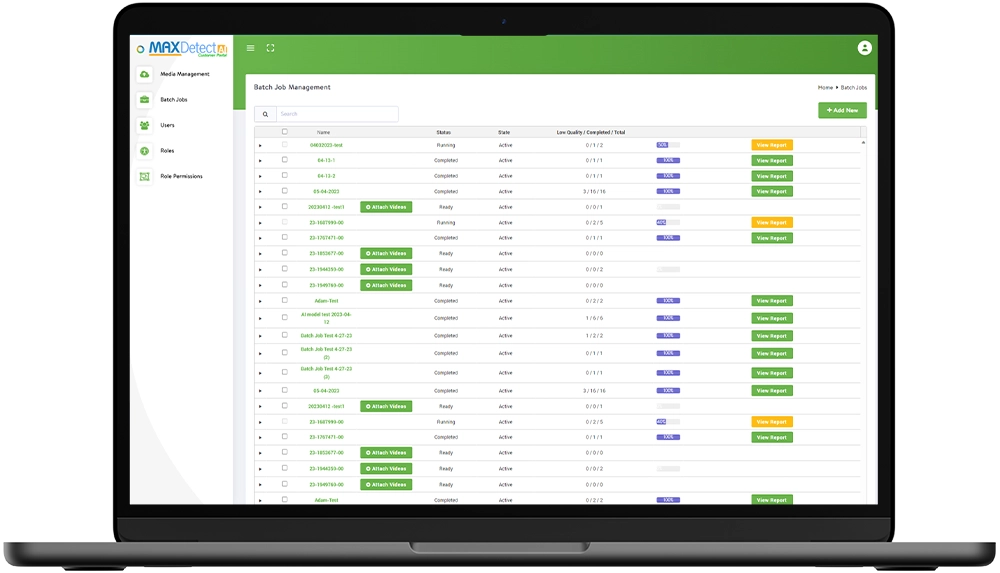

VISUALIZE AND UNDERSTAND RISK WITH MACHINE VISION

Visual inspection tasks are completed with higher accuracy than ever before thanks to our AI model that “sees” and understands the physical world. Cross Bore inspections and more can now be verified with the utmost confidence.

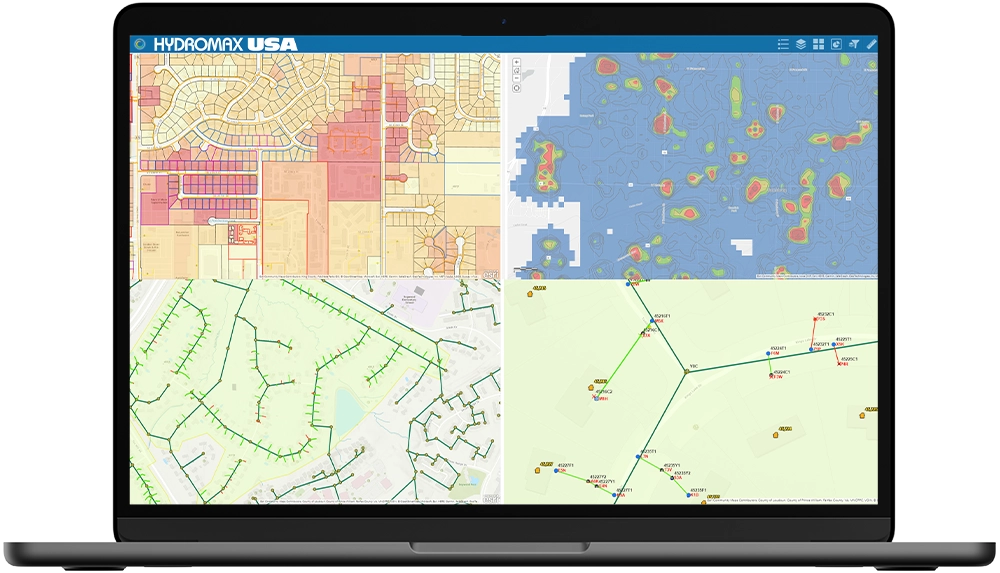

MITIGATE CROSS BORE RISK FAST WITH POWERFUL AI

A powerful predictive model generating actionable insights, MaxPredict gives you clarity into the risk and likelihood of dangerous conditions like cross bores. Our algorithms are trained by an expansive library of real-world data

Actionable business intelligence.

Hydromax USA is propelling the industry forward incorporating utility data into a GIS interface resulting in efficient, user-friendly presentations that deliver:

- Asset details available across multiple departments for project design, project scheduling, and operations control

- Better budgeting by combining asset characteristics from multiple sources of traditionally siloed data

- GIS visual interface that allows users to gather assets by selecting them directly on the screen, turning them into BIM, circuit diagrams, etc.

- Integration with SAP and other data structures

- A structured database to generate meaningful queries and reports with ease.

- GIS databases: High-accuracy asset location and a transition from physical paint marks to a digital response system

Brochure:

Decades of data expertise

As an ESRI Silver Partner, our technology center is home to a dedicated team of over 70 full-time GIS professionals who bring a wealth of expertise in the development of client dashboards. These specialists have decades of experience working with client infrastructure data from across the country providing client information management, infrastructure program analytics, and value-driven reporting.

125K

Miles of cross bore inspections

10K

Cross bores found

1.2M

Laterals inspected

165B

GPS points collected

Connect with a utility expert for a demo.

Submit your details below to learn more about our Advanced Field Services and Utility Solutions.